The MAAV

The design philosophy

-The MAAV design was guided by fundamental aviation design criterias.

Therefor the MAAV uses an inherently safe captive design. i.e all parts are mechanically constrained by the design itself.

-The MAAV mount is staticly balanced by design. And has been validated in tests up to 4500 rpm without any problems. (Max propeller rpm from a Moster 185 @8600rpm /1:2.68 is ~3200rpm)

-The total weight of the 20mm spacer version is ~395g

10mm spacer version will be a fair bit lighter.

The Latching machanism With unique locking mechanism

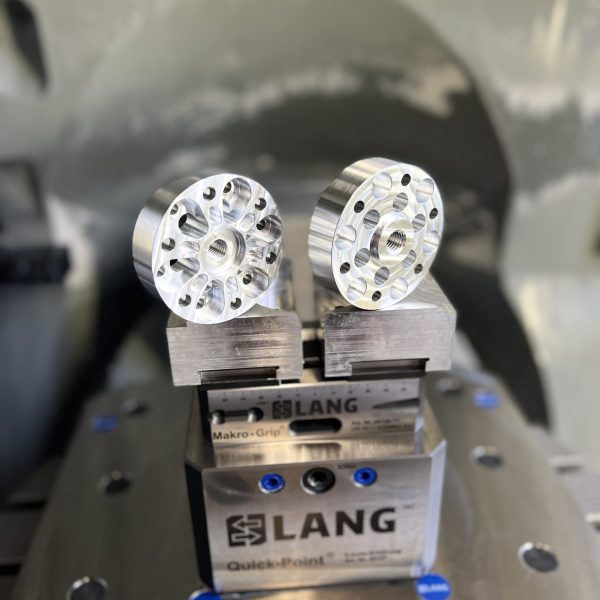

-The latching machanism is 5-axis machined from aviation grade 7075 billet aluminium.

-The uniqe latching mechanism allows for great levrage when tightening the first step by hand, and then applies a great additional force once latched down, all with with very little effort from the operator

-The most important design feature that sets the MAAV aside from other quick mount systems is the anti rotation lock.

When clamped a steel pin locks the rotation of the latching mechanism to the rotationally fixed Pin plate, .

In short this eliminates the possibility of the main bolt to unscrew itself if the lever arm is clamped down, even if it is not tightened hard.

This safety feature is just a additional safety in the event the latching mechanism is not tightened properly. **the mount does not rely on this feature to function if its tightened correctly when installing the prop**

The main bolt

The main bolt is of such importance that it can not be under dimensioned. The bolt should not only handle high momentary loads, but also extended use wich could cause fatigue in a smaller bolt.

-The MAAV uses a M12 (grade 12.9) bolt with form rolled threads. The main bolt is threaded in to the mating threads in the base wich is made from 7075 aluminium and lined with a stainless steel Helicoil thread insert for maximum strength and longevity.

This bolt makes the MAAV a couple of grams heavier. But for the added weight of way less than a car key the safety and longevity is greatly increased.

The Base

-The base is machined from aviation grade 7075 billet aluminium.

-The center thread is lined with a stainless steel Helicoil thread insert for extra strength and wear resistance.

-The guiding pins are made from centerless ground stainless steel pins. The pins are dimpled and pressed in from the back side. Making it practicly impossible for them to come lose.

It comes in two different thicknesses. 15mm and 10mm.

the plastic composite hub

This component is machined form as solid piece of industrial glasfiber reinforced Nylon PA6.

its main function is to constrain the latching mechanism and make it impossible for any part to come loose.

This part is also critical for the balancing of the whole assembly.